Delivering high-quality Components tailored to your industry needs

Savaj Industries is a leading manufacturer and exporter of precision metal castings, specializing in high-quality mould casting solutions for industries such as automotive, aerospace, defense, and more. With state-of-the-art facilities, including advanced CNC machining, induction furnaces, and in-house testing labs, we ensure unparalleled accuracy and durability in our products.

Savaj Industries is your trusted partner for precision-engineered components, meeting the highest global standards.

-

Expert Engineers

Our team of highly skilled engineers specializes in precision casting and machining, ensuring top-notch quality and innovation in every product.

-

Quality Assurance

With a team experienced in international standards, we ensure top notch quality and timely delivery for clients worldwide.

WHY WE STAND OUT?

One-stop solution for all your metal component needs

The facilities are equipped to manufacture complex castings, perform machining, coating, and assembly processes efficiently.

Quick Sample Development Process

We have dedicated employees ready to assist customers who wish to switch to Savaj or have new project requirements.

A technically proficient and professionally managed

We have a team with global experience, ensuring quick and effective communication with our esteemed customers.

Committed to quality and ensuring timely delivery.

We supply precision parts for critical applications on time Beacuse We consider our customer's reputation to be our own

WHO WE ARE?

At Savaj industries, we demonstrate that meaningful change is possible through collective effort and sustainable practices. By repurposing iron scrap, we uphold environmental responsibility while delivering exceptional product quality and customer service. Our model proves that sustainability and excellence can coexist, inspiring others within and beyond our industry. We believe that collaboration and commitment are key to creating a better future, and together, we can drive the positive change the world urgently needs.

WHAT WE STAND FOR?

At Savaj industries, we demonstrate that meaningful change is possible through collective effort and sustainable practices. By repurposing iron scrap, we uphold environmental responsibility while delivering exceptional product quality and customer service.Our model proves that sustainability and excellence can coexist, inspiring others within and beyond our industry. We believe that collaboration and commitment are key to creating a better future, and together, we can drive the positive change the urgently needs

CORE PURPOSE

To be a resourceful guide on the journey toward excellence.

CORE MISSION

The core mission is to enrich people's lives by providing excellent ideas, opportunities, and products.

CORE VISION

To inspire excellence in everyday work and become the dominant leader in the industry.

CORE VALUES

Driven by excellence, trust, consistency, dedication, and empathy, we lead with purpose and initiate meaningful change.

+

Satisfied Clients

+

Active Orders

+

Winning Award

+

Expert Teams

The facilities are equipped with state-of-the-art equipment, including the Sand Plant ARPA-450 and our custom mold handling system. We also have an induction furnace manufacturing all cast iron products. Additionally, our laboratory is outdated with advanced sand-testing equipment from Versatile Equipment LTD, along with a hardness tester, spectrometer, and microscope for thorough product testing before shipment.

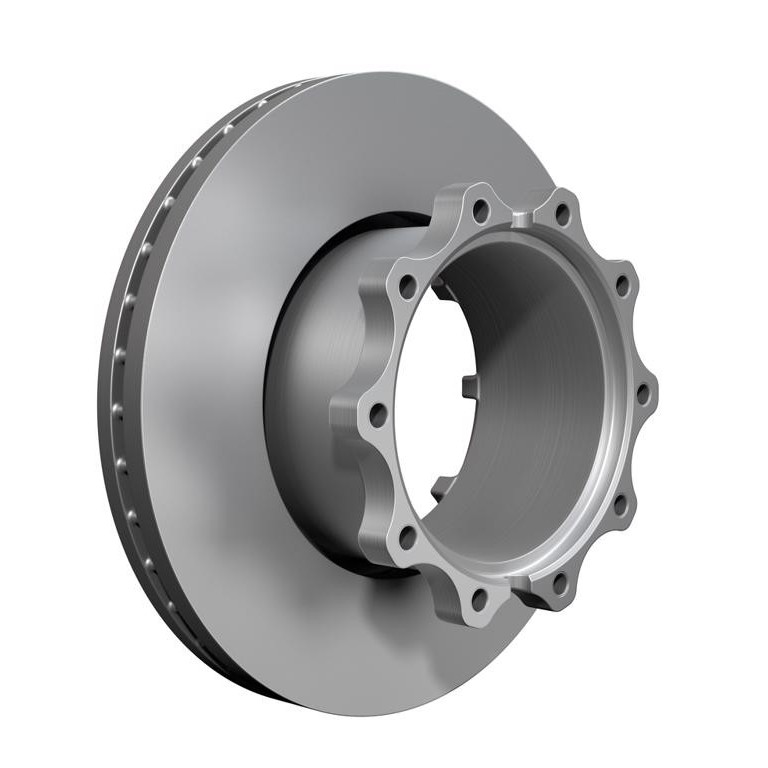

At Savaj Industries, we primarily manufacture Globe valve, disc brake parts and many more. In addition to breck part and industrial valve, the company also manufactures and exports sandcasting components, which and versatile applications across a wide range of industries.

Manufacturing Capabilities & Equipment Specifications

Casting

- Semi Pressure Line

- Max. Mould Size Capacity 550x600 MM

- 300kg & 500kg Induction (Plazma)

- Maximum Workpiece Weight 35 kg

Forging

- 200 Ton Screw Press - (Up Stroke)

- 500 Ton Friction Press - (Down Stroke)

- 2.5 Ton Hummer Press - (Pneumatic Stroke)

Alu. Pressure Die

- Maximum Die Mould 660x660 MM

- Auto Feeder Capacity 7 kg

- Maximum Workpiece Weight 9 kg

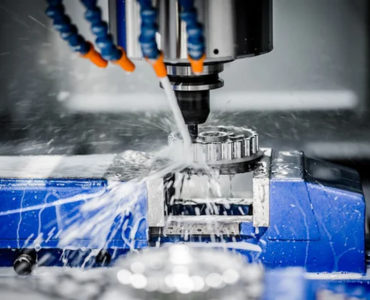

Machining

- In-House Production Facilities

- No Of Machines: 18 Nos

- CNC, VMV, Tnrnmil, VTL, HMC etc...

Cutting-Edge Equipment for Unmatched Quality

The Height Gauge is a precision measuring instrument used to determine the height of objects or to mark and measure vertical dimensions with high accuracy.

- Make: Mahar

- Digital Height Gauge

- Measuring Range: 600 mm

- Expandable Range: 915 mm

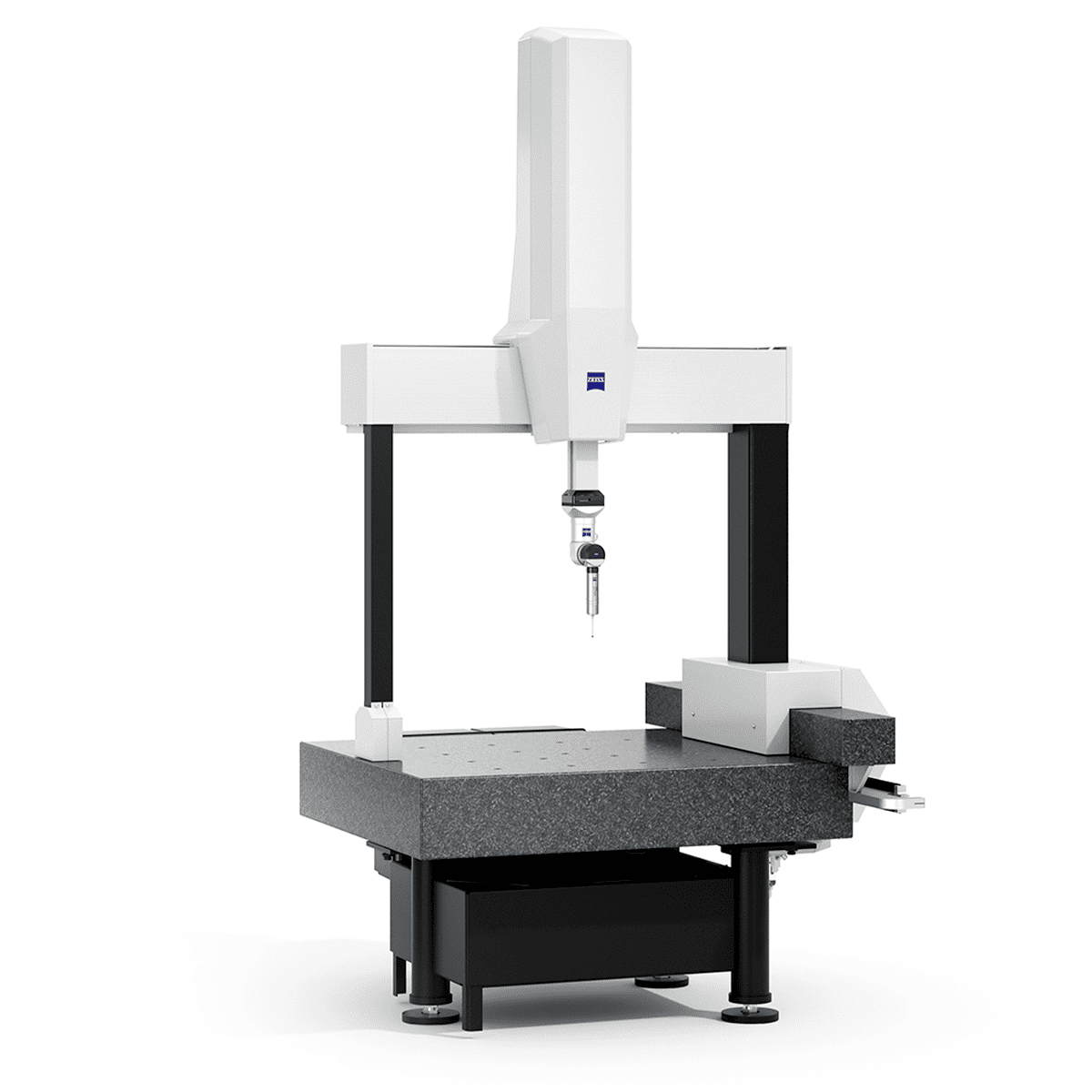

The Coordinate Measuring Machine (CMM) is a highly advanced precision measurement tool used to inspect and measure the geometry of physical objects.

- Make: Mitutoyo

- Non-Contact Measuring

- Scanning Probe

- Reverse Engineering

The Roughness Measuring Machine is used to evaluate the surface texture or finish of a material, ensuring it meets specified quality standards.

- Make: Mahar

- Emergency Solutions Anytime

- Digital Touch Dispaly

- Provide Accurately Ra value

- Adjustable With Height Gauge

- Data Can Be Saved Or Printed

Other Tools to ensure accurate dimensional analysis, material integrity, and defect detection. These state-of-the-art instruments enable us to maintain exceptional quality control and deliver reliable, high-precision products.

- Vision Systems

- Digital Micrometers

- Circular Form Gauge

- Concentricity Gauge

- Hardness Testers

- Optical Comparators

- Air/Profile Gauge

- Crack Detectorness

@gmail.com

Urja Ind. Park,

Shining Gate,

Shapar,

Rajkot-360024